We first looked over the 1968 Angell pipe organ at the United Methodist Church of Westport and Weston in the winter of 2005, having been recommended to the church by our friend K. Bryan Kirk.

What we found in Westport was an organ with many pipes that were well made, but in some cases unusually constructed and by our standards, only roughly voiced. The flue pipes were made mostly with a high content of tin. We suspect Tim Koelewijn was the original pipemaker. Just about everything else in the organ had been made by domestic and foreign supply houses. Overall, quality varied widely. Some things were very neatly done.

Though not altogether under-scaled, the organ did suffer in just about every other way from the prevailing trends in the day it was built. Wind pressures were low: less than two inches in the Great and three in the Swell. Looking at the original stop list, we noted that none of the choruses in the organ were complete, though the organ did boast two Celestes and a Zauberflöte. The reed complement for the organ consisted of a double-blocked French style 8’ Trompette (extended to 16’ in the Pedal) and a 4’ Rohr Shalmei.

The windchest mechanism was a problematic plunger-type solenoid system that had been giving trouble for years. The console was a veneered plywood supply house unit already years beyond its life expectancy. The open contact switching system was dispersed throughout the organ; some of its components had already failed. The wind supply for the entire Great division was provided by a single 18” by 24” reservoir whose internal volume was largely dedicated to its curtain valve.

After an initial tuning of the organ, the church’s new Music Director and Organist, Todd Simmons, pressed me as what could be done to make the organ better. I pointed out that the organ had mechanical and tonal issues, to be sure, but there was something to work with here, some raw material, which with proper attention, could be the basis for a good pipe organ.

Weeks later we met with the Trustees to present our findings, expecting that at some point in the future funds could be raised to finance the organ project. One can imagine my surprise when Mr. Simmons called me a scant few weeks later to inform me a single anonymous donor had stepped forward. How soon could we start? Thus we found ourselves sweating away the summer heat on a stretch of days the following July, packing and removing the pipes which would become the basis for our Opus 645.

In the design process we developed a new specification with input from K. Bryan Kirk. We instinctively sought first to meet the essential requirements of a liturgical instrument, something we believe to be utterly crucial, especially in the case of smaller pipe organs.

Certain early decisions seemed obvious. Given the dry acoustic of the church, the baseline scale of the Great chorus needed to be increased. This chorus was also completed with the addition of appropriately scaled new pipework from 2 2/3’ pitch upward. The cutup schedule of the existing Great capped flute was raised, arched and the stop entirely revoiced. A new independent 4’ Harmonic Flute (based on the unique and very successful scale found in our historic Opus 178 at St. Charles Borromeo in Brooklyn) was constructed and voiced. Over the course of the project nearly every zinc pipe in the organ made its way through our pipe shop: frozen metal caps were freed, tuning inserts and toes replaced, seams and scrolls repaired. Being left in a raw state, many of the zinc pipes had an unsightly powdery white oxidation. We removed this, and gave all zinc basses a sealing coat of varnish to protect them.

Where before the Great division of the organ had seven ranks, it had now eleven. To provide for this expanded division adequately, we built a new, larger reservoir. The rest of the organ’s wind system was rebuilt and reengineered as the new design required.

In the dealing with the Swell division, again certain decisions seemed obvious. The only marginally useful 4’ Rohr Shalmei was replaced with an 8’ Oboe. All of the existing Swell flues were revoiced and new pipework was added to the Swell flute chorus, which was completed to 1 3/5’ pitch. The existing Trompette was kept, though carefully cleaned up and regulated.

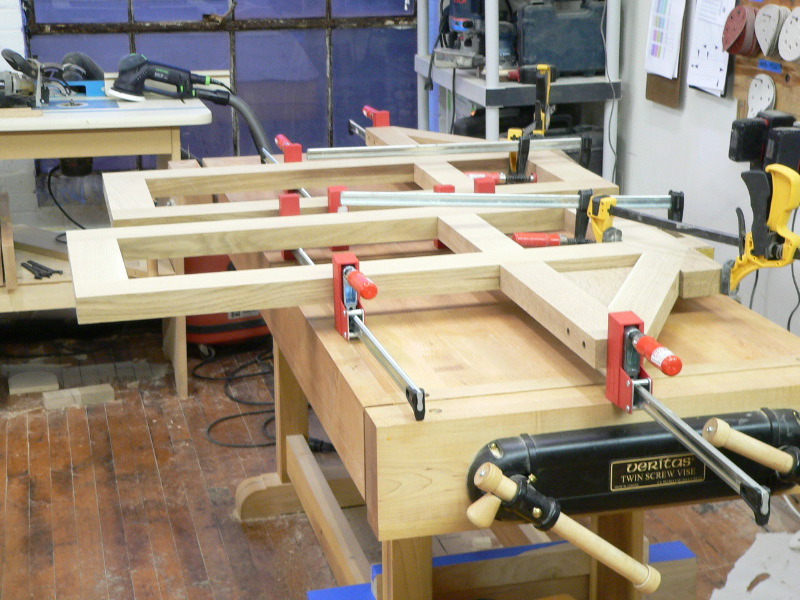

In our recently expanded East Hampton shop I concentrated on the construction of the console, while our shop foreman constructed new windchests whose design was first developed for our organ at St. Ann’s in Bridgehampton. The unusually short feet of the 8’ flute basses made for some interesting pipesetting. New offset chests were provided for everything save the original Pedal Subbass, a mammoth mahogany affair that only needed rebuilding.

The new console was based on our current terrace-jamb design with several embellishments. Improvements on the existing design include a slightly deeper cabinet with an added horizontal stile, raised panel work, additional applied moldings, hand- carved brackets, a two-piece knee panel and solid walnut music desk, the latter being picture framed with the same quarter-sawn white oak used for the carcass and façade.

The console features an integrated solid-state capture and control system with fully programmable features, MIDI interface and our standard complement of rear-fulcrum keyboards with basswood levers. The oblique drawknob heads are a reproduction of our 19th Century design. Respected organists who have played it have described our console at Westport as “elegant and comfortable.”

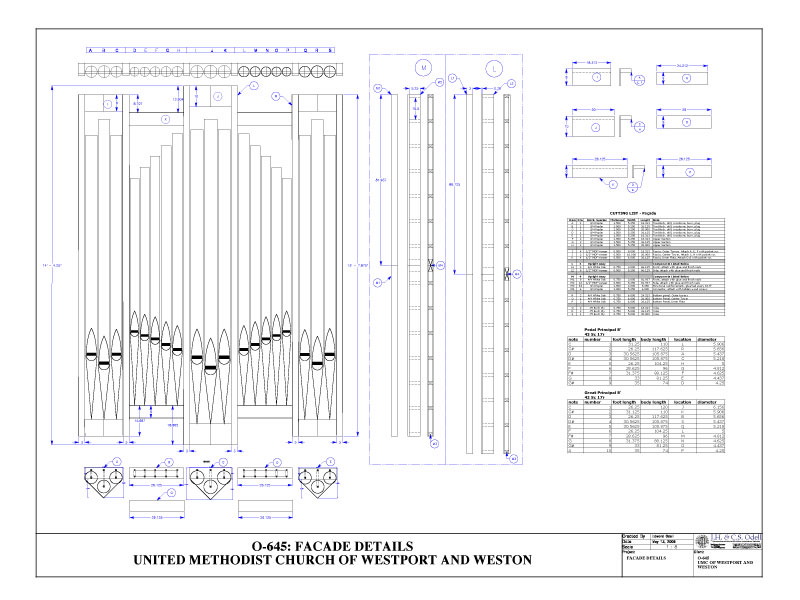

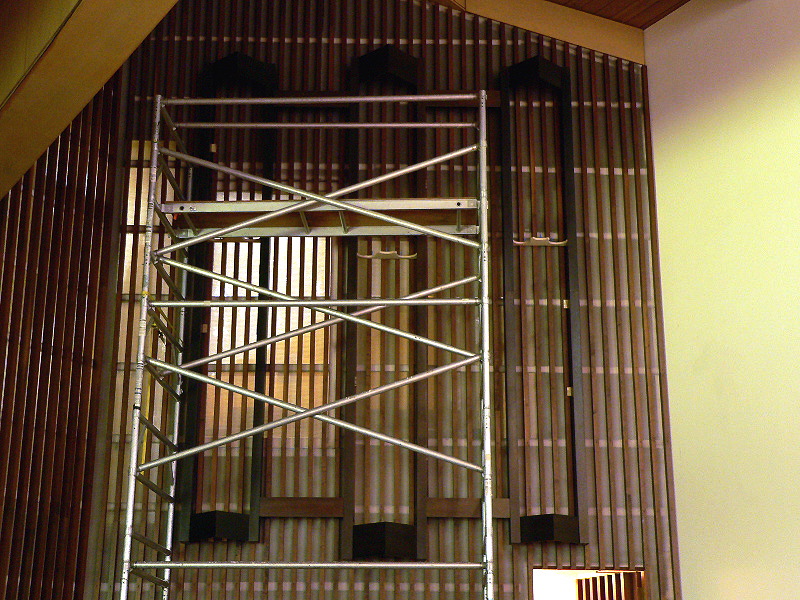

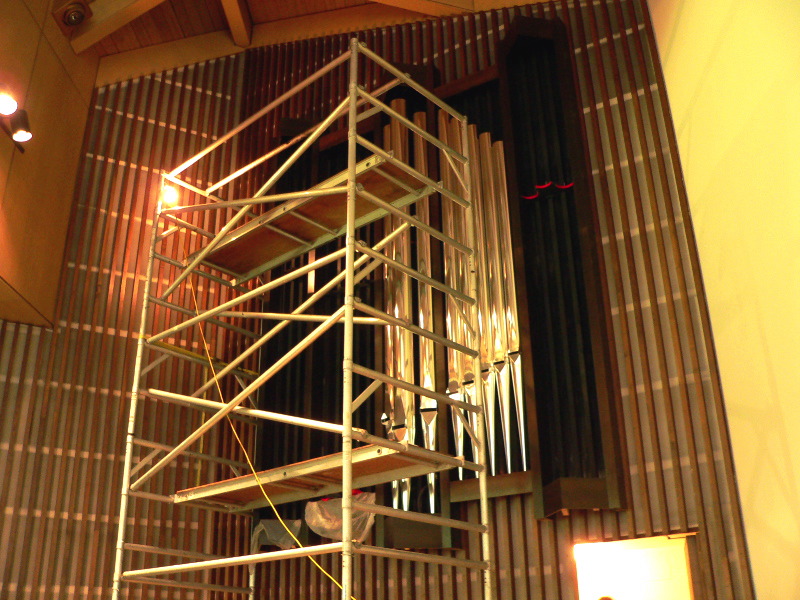

Our design of the façade was in part born of necessity. Since both the manual and pedal principal stops were being rescaled, new bass pipes would be required. We naturally needed to make the most of the existing chamber space, and one of the simplest ways to do that was by moving the basses of these stops out into a façade.

Every pipe in the façade is functional. The bass notes of the Great and Pedal principals are polished aluminum, made to our specifications by Matters, Inc. of Hermosa, South Dakota. The pipes are arranged in three towers and two flats and the overall height of the case tops out at fifteen feet, mounted roughly ten feet above the sanctuary floor. The style of the casework is deliberately simple, so as to be in harmony with the appointments of the church sanctuary.

The sanctuary space in Westport could be described as a postwar-modernist take on the “Akron Plan”, less the adjoining Fellowship Hall. Three sets of pews radiate from the altar and pulpit up front, with organ and choir off to the left. The space over the altar is open with a ceiling height of approximately forty feet. This intersects with a lower A- Frame suspended transverse over the pews. From there the ceiling slopes downward to the rear of the pews to meet a northeasterly facing wall that is mostly glass. The floor is a simple concrete aggregate. Thankfully carpet and pew cushions are absent. More simply described, it is a space with a great deal of cubic volume, but not overly reverberant.

Throughout the process we gave a great deal of thought to what levels of power would be appropriate for the various tonal resources of the organ. Our concerns about sufficient tonal egress from the chambers were put to rest when we experienced how well the organ spoke into the room. In the tonal finishing process we were pleased to discover how our scaling and voicing decisions suited the space. With a well-balanced variety of 8’ tone available, the organ easily leads congregational singing in a variety of settings.

Odell opus 645, United Methodist Church of Westport and Weston

“One of the most impressive enhancements with the new organ, aside from the exquisite facade, is the quality of sound as well as the power behind it. What we have now is an instrument that easily leads our congregation in singing, as well as providing full, but subtle, accompaniment for the choir anthems. I can honestly say that at every step of the way, Mr. Odell and his firm have not only met, but exceeded my expectations with our new organ and have gone above and beyond the call of duty to deliver an instrument which is even better than the original proposal stated.”

Click for stop list: Odell Opus 645

Click below to listen to Jonathan B. Hall playing the first movement of the Concerto in a minor after Vivaldi, S. 593 by J.S. Bach on our opus 645:

“In the design process we developed a new specification with input from K. Bryan Kirk. We instinctively sought first to meet the essential requirements of a liturgical instrument, something we believe to be utterly crucial, especially in the case of smaller pipe organs.”

“Once the installation commenced, it was exciting to see how beautifully designed and well made all the components of the organ were, both inside and out. During the tonal finishing, it was gratifying to witness the attention to detail in balancing each stop and the various ensembles to provide the church with an instrument to fulfill the original mission. It was refreshing to hear from the builder that materials and workmanship were never an issue: they simply insisted that in every aspect things be done thoroughly, with the highest level of attention to detail. I am extremely pleased with the final result, as is the organist and the church.”

Console: Odell opus 645